Pertinent

Versions of the “rocket stove” principle have been manufactured for about 90 years, so the concept must be older. Above is a cheap and quick example of a rocket stove made with about seven tin cans. The barrier between the inside chimney of small cans and the outside layer of large ones, is insulated with sifted wood ashes. Rocket stoves are efficient for cooking because they burn hot and use very little fuel. The “rocket” name undoubtedly stems from the vigorous manner in which air, flame and smoke are all drawn into the chimney.

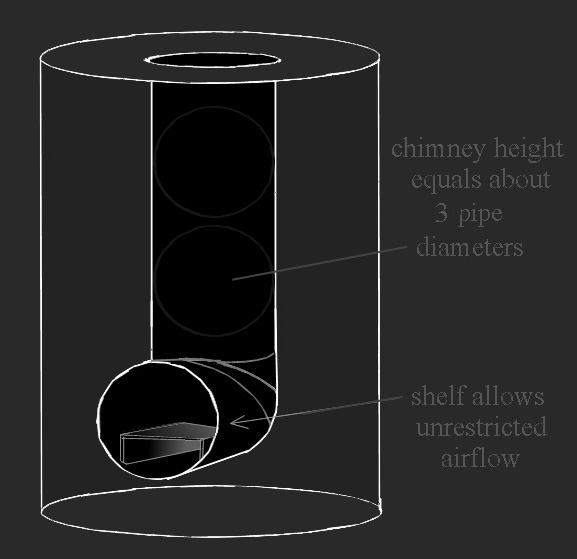

For free standing little cook stoves and water heaters the optimum chimney height might be a little less than three times whatever inside diameter is actually chosen for the chimney. These proportions seem to engender the best draft.

Once a fire has been ignited it takes a few minutes for the stove to become normalized. Once hot and working correctly these little stoves consume almost all the volatiles in smoke and leave little pollution. Using just dry twigs these stoves are capable of reaching 1,600 – 1,700°F (926°C). * That’s a temp high enough to melt tin, lead, zinc, antimony, magnesium, aluminum and lava – but not silver, gold or copper.

Iron stoves or the ‘tinplate’ steel found in a soup can will not stand up to long term heat of this degree because of the accelerated rate of oxidization. For this reason a stainless steel, ceramic or refractory version would be desirable for stove longevity.

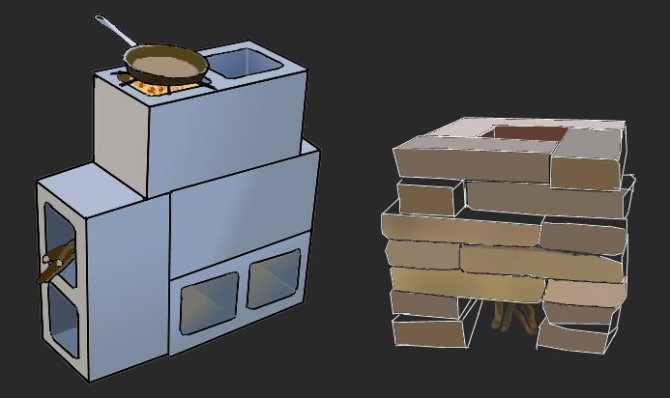

Slick stoves working upon the rocket principle have been made with cinder blocks and stacked bricks. This link is to a rocket stove manufactured in China. These are practical products but seem a bit costly.

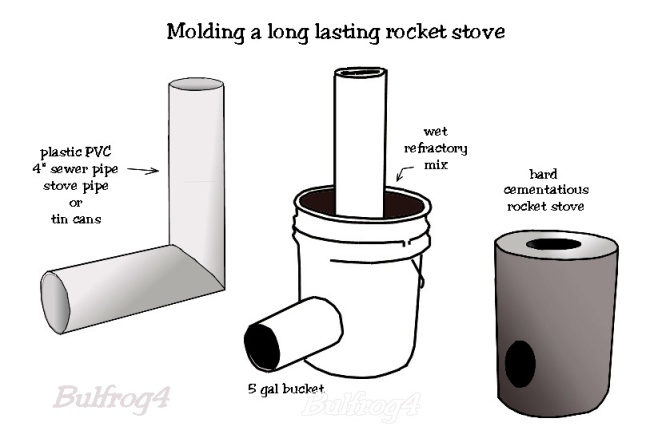

A long lasting cementatious rocket stove can easily be made at home. This image (idea robbed from a video) depicts creating a mold from plastic sewer pie and a 5 gallon plastic bucket. Yes the mold could be filled with plain cement but a refractory mix would be more desirable. A concrete rocket stove would conduct heat and become hot to the touch and would also be heavy to move. A stove cast of proper refractory would be lighter weight and insulated, allowing desirable higher heat inside the chimney.

Opinions and examples of refractory mixes vary widely. Perlite and vermiculite are frequently listed as light weight insulating ingredients in refractory mixes. If the intended function is not too demanding, wood sawdust or peat moss might substitute as the light weight, insulating ingredient. Perlite is a volcanic glass that has been ‘puffed up’ like popcorn (with the help of escaping steam when it was created). You’ll frequently find little individual white beads of perlite mixed in with commercial potting soils, or sold in bulk at plant nurseries as a soil amendment. Exfoliated vermiculite possesses many of the same qualities as perlite. Fireclay is an ingredient used in the refractory of brick, ceramic and glass kilns, because few other building materials can repeatedly withstand such high working temperatures. An easy to remember recipe for an adequate refractory mixture would be four equal parts each of sand, Portland cement, fireclay and perlite (or vermiculite). Those proportions could be tweaked a bit to reduce sand and cement (1.5 sand, 1.5 cement, 2 fireclay, 2 perlite).

When casting a mixture like this it is important to use as little water as feasible to ensure the strength of the concrete (refractory). Do not forget to allow adequate space at the bottom for insulation of the chimney and remember to tamp this first, with a stick, before filling the remainder of the mold. A wire skeleton or armature of some sort would greatly enhance the long term resilience of such a cast.

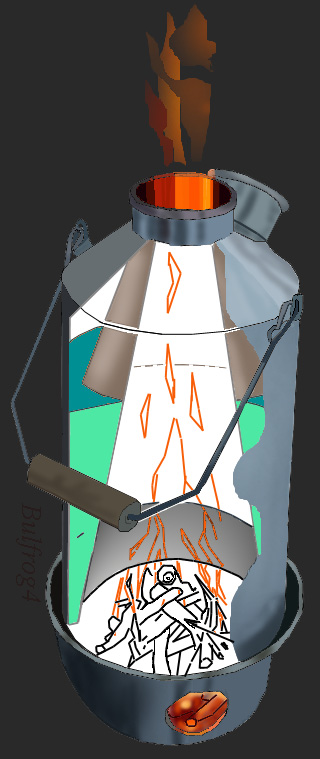

Two centuries or more ago, the chimney in the center principle was being exploited by expensive handmade self heating teapots known as samovars. Manufactured portable utensils for heating or sanitizing water outdoors began to be seen in numbers for the first time however during WWII, when the New Zealand Army issued their soldiers with mess kits containing jacketed kettles. ‘Storm kettles’ or ‘volcano kettles’ work well in windy or rainy weather. Fuel from twigs to straw to buffalo chips can be found almost anywhere and cost nothing.

Not commonly found in American sporting goods stores, these kettles are made by several little companies and are produced in either aluminum or stainless steel versions. Rather than pack into the woods a stove that requires special fuel (sterno, denatured alcohol, hexamine tablets, paraffin wax, kerosene or naphtha (white gas)) it seems more logical to carry one that simply uses fuel which can be picked up from the ground.

Thermette: Ghillie-kettle: Eydonkettle: Kellykettle

——-

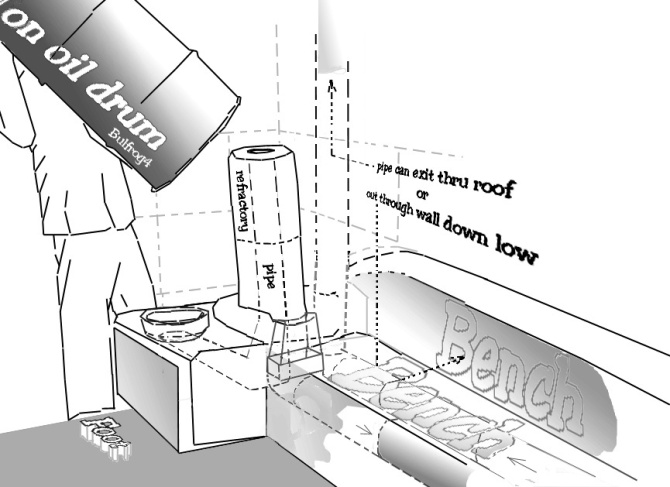

For some time now some people have been using a larger form of the rocket stove, known as a “mass heater”, to warm the home. In this case the exhaust from the chimney is captured and turned downward, then circulated through a wall, the floor or a banco (bench). The masonry in the wall, floor or bench acts as a thermal mass or heat sink that collects the heat and releases it slowly. So from the illustration above an oil drum or other metal hood accomplishes the first heat exchange to the room’s atmosphere. Any remaining heat is ideally captured by a thermal mass before the exhaust is finally released to the outdoors.

A few examples of these thermal mass heaters are found almost all over the world. It would be very feasible to pre-heat water for the home by wrapping a water line around a rocket stove’s chimney. Potential construction concerns for building a mass heater of this type include ensuring that the draw of the stove is sufficient to push exhaust through a long ductwork. One critical dimension is the distance between the top of the chimney and the hood (drum). Some people brag that the amount of firewood needed to warm their house was reduced by 75% after resorting to a ‘mass heater’. One should consider however the extra time spent splitting wood into pieces small enough to feed into this stove, and the extra attention probably required to keep the (fast burning) stove continually fed. Depending on size it may take several hours to several days to equalize the thermal mass, so hopefully in the meantime the house would be equipped with an auxiliary source of heat.

Added 7/27/2016

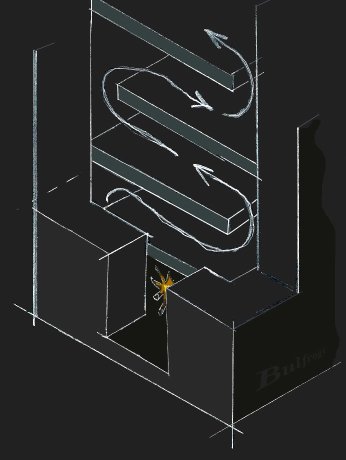

The rocket stove mass heater takes its idea from the much older masonry stoves and or ceramic stoves of Europe and Russia. Usually constructed of brick and covered in tile these often massive heating appliances are at least one thousand years old in design principle yet are still “greener” and more efficient than modern heating alternatives.

The typical “tulikivi” (Finnish), “kachelöfen” (German), “kakelugn” (Swedish) or “pechka” (Russian) oven stoves only need to be fired about twice a day to provide a continuous 24 hour heat. In some homes the people sleep on them, or may also bake with them. When designed well they burn very hot and therefore leave little creosote buildup behind. Inside the fire’s exhaust must furl around a labyrinth of baffles before it can escape, providing time and surface area for energy transfer.

In the last century or so of newer building construction, massive masonry heaters like these were usually replaced with much smaller coal, oil or natural gas burning alternatives.

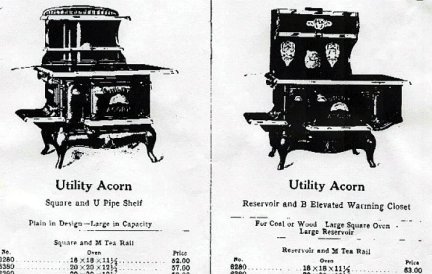

The cast iron wood cookstove became a favored house heating appliance in America homes between the 1870s and the 1920s. They were advertised in newspapers and mail order catalogues and were manufactured by a host of different companies like ACME, Acorn, Garland, Majestic, Monarch, Peninsular, Pilgrim and Sterling. These wood stoves or ranges could act as energy centers perhaps for the whole house and they supposedly baked a better loaf of bread than any modern gas or electrical counterpart. Different models came with different options including ornate chrome (probably nickel) trim, hot water reservoirs, foot latch, thermometers, broiler drawers and secondary warming chambers. Cooking on such a stove could require much patience to establish the fire, because in addition to the firebox some models came with an adjustable main draft regulator, check draft regulator, stove pipe damper and an auxiliary damper. It was standard practice for a housewife to keep a stock pot on the back of the stove, where she put leftover scraps of meat and bone. Comfortable and desirable in the winter – these stoves could become beast to cook with however on hot summer days.

Pertinent links-

———————————————————-

After reconsideration the project on the right above will be redesigned from an “L” shape to a “J” shape, to allow fuel to be fed from the vertical axis. Sheet metal screws will be reversed so that they can be removed from the inside. After that cans are to be wrapped in plastic food wrap and a chicken wire armature will be wrapped around the cans – suspended about an inch away. After that a refractory mix will be slathered over the armature to a depth of about 2 inches. Some of the metal cans will be too hard to remove initially, until years afterwards when the rust can then be pulled from the refractory easily.

(Slideshow below added August 2016)

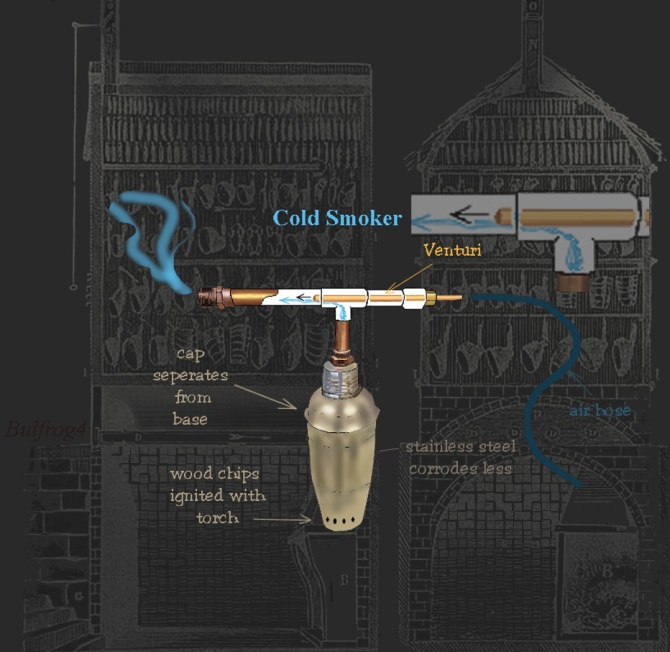

The image above is a little incongruous with the topic of rocket stoves, but since it is related to fire and cooking and was available, it is included now. Methods for cold meat smoking are diverse and numerous. This image depicts a homemade variation of a commercial product which blows a steady stream of wood smoke into a meat holding chamber. The main feature is the venturi which in this case is powered by a tiny air pump (like one used to aerate a fish aquarium). The can below the homemade copper venturi needs a lid that will open and close; to insert wood chips or remove ashes. The can needs some holes in its bottom so that combustion air can be drawn up through the smoldering woodchips. Twelve to sixteen ounces of (hardwood) wood chips should provide about three hours of smoke.

There is not enough time and space left in this installment to adequately explain the important details of meat curing. Remember that the wealthier half of civilization has only possessed artificial refrigeration for the last century or less. Salt and smoke dehydrate -bloody raw meat. Salt and smoke and cold weather have historically been the preferred tools for preserving meat by protecting it from bacterial spoilage. Traditionally, smokehouses worked continually around the clock and pretty much throughout the year. It is recognized by some that today’s commercial hams and bacons will putrefy long before they should (had they been properly cured and smoked by traditional methods rather than by quick methods).

In 1832 it was discovered that pyroligneous acid from creosote in wood smoke was the antiseptic preservative which protected meat. Today commercial meat processors commonly inject into boned meat, salt, nitrites, nitrates and sulfides. Before slaughter the animal may have been fed antibiotics, steroids or additives like ractopamine hydrochlorid. About 70% of all chicken and beef sold in the U.S. and Canada is actually treated with carbon monoxide before you buy it. The best way to tenderize meat without resorting to chemicals, is to cook it slowly. Nowadays the best reason for treating meat to wood smoke (longer is better) is for the taste.

You completed a few nice points there. I did a search on the theme and found nearly all persons will consent with your blog.

I really appreciate this post. I’ve been looking everywhere for this! Thank goodness I found it on Google. You’ve made my day! Thx again.

with an angled feed ramp you can add a mesh to support long pieces of wood and extend burn time. the mesh prevents the fire from creeping up from what I’ve read. I could be wrong though. Thanks for the blog, very interesting.

My friend first found your blog on Google and she referred your blog to me.`-;,”